1. Description

O-Ring seals are suitable for various mechanical equipment. It has sealing function in static or motion state. When it was in the medium of specified temperature, pressure, different liquid and gas. There have many sealing elements used in machine, ship, automobile, aerospace equipment, metallurgical machinery, chemical machinery, construction machinery, building machinery, mining machinery, petroleum machinery, plastic machinery, agricultural machinery and various instruments and apparatus. O-Ring seals mainly used for static sealing and reciprocating motion sealing. When it used in rotary sealing, it was only limited in low speed rotary sealing device. O-Ring seals generally installed in the groove of rectangle cross section. O-Ring seals have good sealing performance in the situation of oil resistance, acid and alkali resistance, wear resistance, chemical resistance. O-Ring seals are most widely used in hydraulic and pneumatic system.

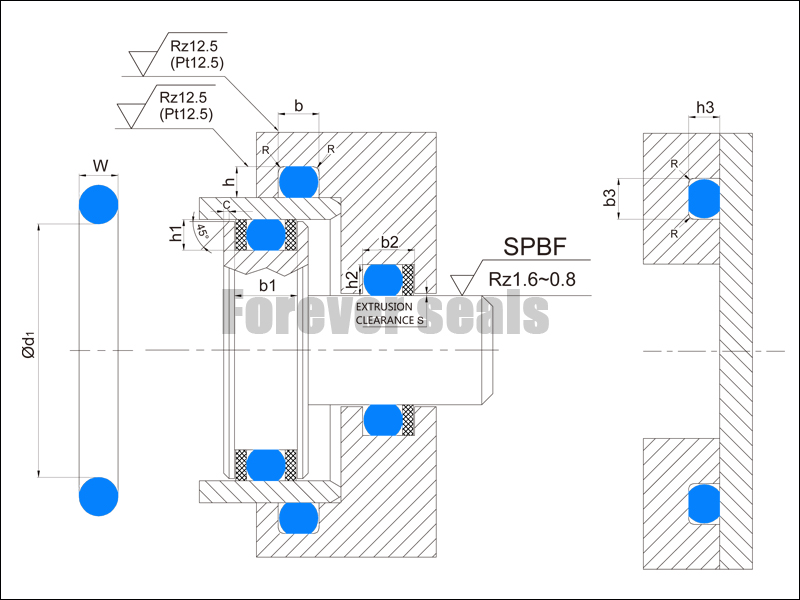

2. Installation Recommendation

3. Materials

EPDM has a great acceptance in the sealing world because of its excellent resistance to heat, water and steam, alkali, mild acidic and oxygenated solvents, ozone, and sunlight (UV). These compounds also withstand the effect of brake fluids and Skydrol" and other phosphate ester-based hydraulic fluids. EPDM compounds are not recommended for gasoline, petroleum oil and grease, and hydrocarbon environments.

4. Product Display