1. Description

O-Ring seals are suitable for various mechanical equipment. It has sealing function in static or motion state. When it was in the medium of specified temperature, pressure, different liquid and gas. There have many sealing elements used in machine, ship, automobile, aerospace equipment, metallurgical machinery, chemical machinery, construction machinery, building machinery, mining machinery, petroleum machinery, plastic machinery, agricultural machinery and various instruments and apparatus. O-Ring seals mainly used for static sealing and reciprocating motion sealing. When it used in rotary sealing, it was only limited in low speed rotary sealing device. O-Ring seals generally installed in the groove of rectangle cross section. O-Ring seals have good sealing performance in the situation of oil resistance, acid and alkali resistance, wear resistance, chemical resistance. O-Ring seals are most widely used in hydraulic and pneumatic system.

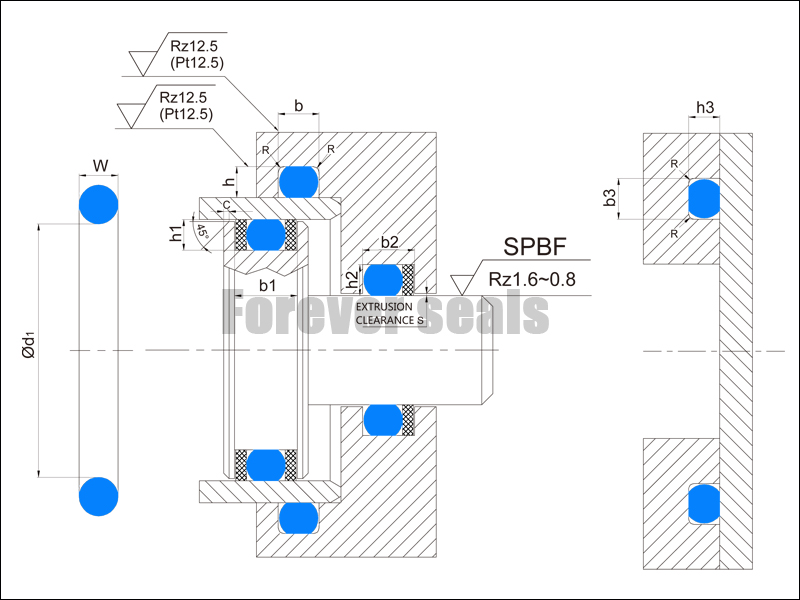

2. Installation Recommendation

3. Material

FKM O-rings should be considered for use in aircraft, automobile and other mechanical devices requiring maximum resistance to elevated temperatures and to many fluids. FKM resist mineral oils and greases, aliphatic, aromatic and also special chlorinated hydrocarbons, petrol, diesel fuels, silicone oils and greases. It is suitable for high vacuum applications. Many fluorocarbon compounds have a higher than normal mold shrinkage rate, molds for fluorocarbon products are often different from molds for Nitrile.

4. Product Display